News

Enhydra designs an integrated sand jetting system for a new FPSO

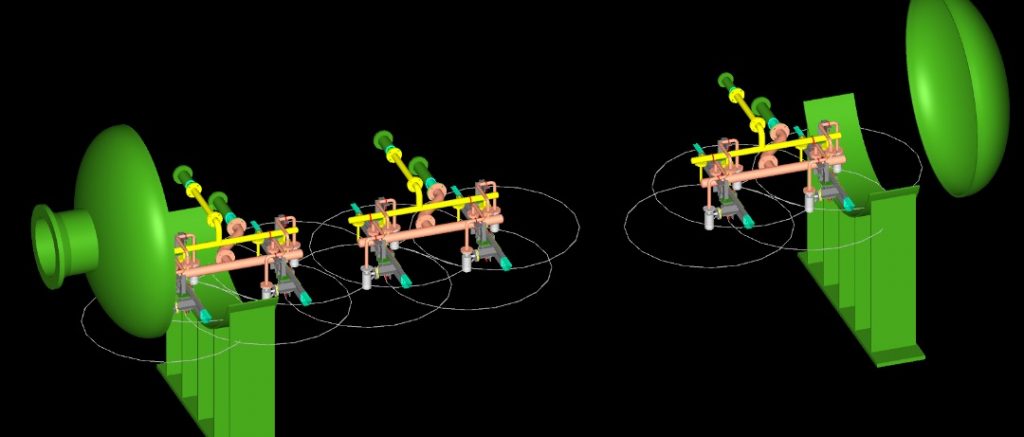

Working with multiple systems integrators and large equipment vendors Enhydra has been responsible for the integration of a complex online sand jetting arrangement on a new FPSO. Enhydra received 4 separate purchase orders, providing online sand jetting for the HP, MP and LP Separators, the Electrostatic Coalescer, the Produced Water Treatment Train and the Closed Drain Vessel. All vessels operate in different areas of the FPSO with different process conditions and different elevations. The integrated online jetting system has been designed with a combination of eductors that enhance a slurry transportation system that takes all the solids to a single collection and sand cleaning location, where it is treated using a Sand Wash Unit (SWU) with process design and internals also by Enhydra.

The arrangement and installation of sand jetting nozzles in the vessels is based on Enhydra’s CALM Jetting System:

C – Cyclonic Fluidisation that sends a radial jet of water to a specific zone

A – Area, of the targeted radial zone of influence under the jetting nozzle

L – Low interference with minimal disturbance of the process and separation interface

M – Matrix, is the arrangement of the nozzles to cover the vessel.S

At the heart of the CALM Jetting system is Enhydra’s Radial Sand Removal nozzle. Carefully designed and developed for high efficiency extraction of settled solids without the disturbance of the process.

On this project all the vessels and internals were new build. However, the Enhydra CALM jetting system has been developed over many years to be retrofitted to existing vessels (via manway) when sand becomes a problem.